Welcome to the insights from Denmark's first PFAS Test Center, where we have finalised out PFAS treatment in soil. In today's blog post, we are ready to share initial results and observations with you:

Rethinking PFAS remediation

What if a clever heating approach can:

- optimize degradation/mineralization of PFAS in soil with no or limited after treatment required?

- minimize your energy consumption and remove the traditional energy intensive process of thermally oxidizing the wet off gas?

- reduce your overall CO₂ footprint?

These are the topics amongst others we are researching in our PFAS pilot test in Korsør.

If you haven't heard about this pilot project yet, we recommend to catch up in the Blog post #1 and #2.

What was treated?

Our pilot project focuses on 36 tons of PFAS-contaminated soil from the fire training facilities. The soil generally consists of sand and a high content of clay.

The pilot project aims to demonstrate PFAS remediation effectiveness by treating the soil to meet Danish EPA criteria:

- 10 µg/kg soil for the sum of PFAS 4

- 400 µg/kg soil for the sum of PFAS 22

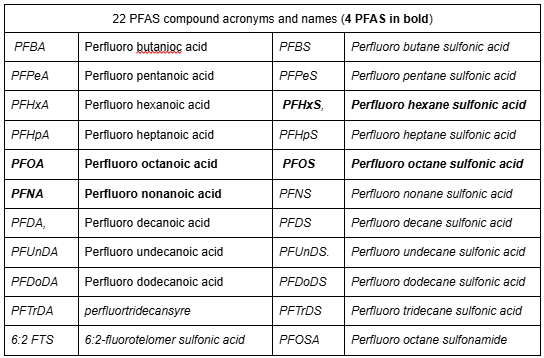

PFAS 22: PFBA, PFPeA, PFHxA, PFHpA, PFOA, PFNA, PFDA, PFUnDA, PFDoDA, PFTrDA (perfluortridecansyre), PFBS, PFPeS, PFHxS, PFHpS, PFOS, PFNS, PFDS, PFUnDS, PFDoDS, PFTrDS, PFOSA, 6:2 FTS. PFAS 4 are marked with bold . For full compound names, see end of text.

Our approach

We heat the soil to 350 - 450 °C using renewable electrical energy. In order to increase in-situ degradation/mineralisation of PFAS in the soil, we extract as little air as possible.

The water we evaporate we condense instead of e.g. thermal oxidation of the wet off gas. Thereby we continue the quest of using a minimum of energy. All this is combined in a highly robust and operational treatment system.

Heated box setup

Heated box setup

Operational treatment timeline

We started with gradually heating the soil to dry it out. In the next 30 days we subsequently heated the soil to 350 - 450 °C before heat was turned off. A total of 18 temperature monitoring points (TMP) in the 20 m³ soil were utilized to keep track of the conditions the soil has undergone. Along the heater cans 11 TMP’s tracked the heater temperature.

Soil temperature profiles over the course of the project

Soil temperature profiles over the course of the project

During the heating a total of 4,5 m³ of water was boiled off and condensed while soil ventilation was kept at 1 m³/h.

Soil concentrations prior and post thermal treatment

The heated soil was sampled after cooldown. A total of 36 soil samples have been analysed. As mentioned, treatment temperature has been monitored for all samples. None of the 4 PFAS (PFOS, PFOA, PFHxS and PFNA) are detected in the soil samples treated at 350°C. Three samples treated at 250°C have a sum of 4 PFAS ranging from 0.1 to 2.0 µg/kg. The sum of 4 PFAS concentrations prior to thermal treatment ranged from 56 to 370 µg/kg with an average of 170 µg/kg.

Correspondingly none of the other target compounds of 22 PFAS are detected in the soil samples treated at above 350°C. The concentrations of 22 PFAS prior to thermal treatment ranged from 65 to 390 µg/kg with an average of 190 µg/kg.

Condensate and vapor analysis insights

The condensate produced during dry out of the soil has been collected in 1000 L Intermediate Bulk Containers (IBCs). One sample from each of the four IBCs collected during the dry out has been analyzed. The sum of 4 PFAS ranged from 4 to 15 ng/L. This means that in total 0.001% of the 4 PFAS mass was driven off the soil during dry out and condensed with the steam. The shorter chain PFAS are more prone to evaporation and hence the sum of 22 PFAS concentration in the condensate ranged from 25 to 100 ng/L, giving a total of 0.004% of the 22 PFAS mass driven off the soil during dry out and condensed with the steam.

Vapor analysis per Other Test Method 45 (OTM 45) for semivolatile PFAS and OTM 50 for volatile PFAS has identified PFBA, PFPeA, PFHxA, PFHxS and 6:2 FTS as well as highly fluorinated alkanes in the outgassing from the soil. These are low levels and having in mind the very limited ventilation (1 m³/h) these could easily be overlooked due to dilution if the ventilation rate had been higher.

Mass spectrometry results

Outgassing from the soil was monitored online during the heating process using a High Resolution Mass Spectrometer (HRMS). The real-time measurements have identified and tracked the outgassing of hydrofluoric acid, a number of perfluorinated carboxylic acids (PFCAs), organic acids and hydrocarbons. Estimated concentrations are in the 10-1000 ppt range depending on the compound. However more data analysis is to be done in order to trend the significant amount of spectres from the treatment.

Concentrations in air extracted from the heated box over the course of the dry out and heating phases derived from HRMS real time measurements using the AIM iodide ionization method.

Concentrations in air extracted from the heated box over the course of the dry out and heating phases derived from HRMS real time measurements using the AIM iodide ionization method.

The results of real time HRMS agree with the compounds identified in OTM 45 and OTM 50 gas samples and recovered in the condensate.

What is next?

So far the pilot test has confirmed that low temperature (350 °C) is a sufficient target temperature for the 22 PFAS. The chosen thermal treatment strategy has resulted in limited volatilization of PFAS thus optimizing the vapor residence time in contact with the hot soil allowing time for degradation and mineralization.

We are still waiting for the soil and condensate samples for further analysis. Top assay (TOPA), extractable/adsorbable organic fluorine (EOF/AOF), total fluorine (TF) and inorganic water soluble fluoride are with the analysis lab along with samples of spent defluorinator catalyst and spent activated carbon.

More data analysis is ongoing, especially on the HRMS during the summer, but results are very promising and the approach is under evaluation in terms of scaleability, operational predictability, CO₂ footprint comparison with equal techniques etc.

Stay tuned for the last blog post #4 and a webinar expected in September.

Be sure that you have subscribed to our newsletter to get project updates and webinar invite.

The information contained herein is based on the Veolia group's understanding and know-how of the scientific, regulatory and technical fields discussed herein as of the time of publication. No contractual undertaking or offer is made on the basis hereof and no representation or warranty is given as to the accuracy, completeness or suitability for the purpose of the relevant information.