Welcome to the insights from Denmark's first PFAS Test Center, where we continue researching PFAS treatment in soil. In today's blog post, we are ready to share initial results and observations with you:

As demand for proven technologies for both investigation and remediation of PFAS-contaminated soil is growing, Denmark has established its first national PFAS Test Center. The facility serves as a testing ground where companies and research institutions can validate and improve their PFAS detection and soil remediation technologies under field conditions.

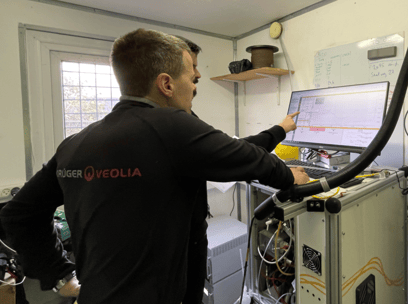

After seven years of extensive laboratory research (described in our Blog), we are scaling up our PFAS soil treatment research to field conditions. In 2024, the Danish EPA granted Krüger, a subsidiary of Veolia, a pilot-scale demonstration project at the national PFAS Test Center. The project is now in operation and in this article, we'll share our initial findings and address key questions about PFAS treatment at field scale.

Inside the Korsør site: Why this location for testing?

The test site is located at the Korsør Fire Training Academy on the west coast of Zealand, Denmark. Operating since 1969, the academy used fire-fighting foam containing PFOS until 2001. Decades of training activities have resulted in extensive PFAS contamination, making it an ideal location for testing soil remediation technologies under real-world conditions.

Photo: Korsør fire training academy and surroundings (Courtesy of Regional Knowledge Center for Environment and Resources)

Photo: Korsør fire training academy and surroundings (Courtesy of Regional Knowledge Center for Environment and Resources)

The test center was established in 2022 through a strategic partnership between:

- Slagelse Municipality (site owner and local environmental authority)

- RESC Rednings- og SikkerhedsCenter (the active fire fighting academy)

- Region Zealand (regional environmental authority)

What are the project goals? Treatment criteria and research objectives

For this project, the client has excavated and pre-analysed 36 tons of PFAS-contaminated soil from the fire training pits. The soil generally consists of sand and a high content of clay.

The pilot project aims to demonstrate PFAS remediation effectiveness by treating the soil to meet Danish EPA criteria:

- 10 µg/kg soil for the sum of PFAS 4

- 400 µg/kg soil for the sum of PFAS 22

PFAS 22: PFBA, PFPeA, PFHxA, PFHpA, PFOA, PFNA, PFDA, PFUnDA, PFDoDA, PFTrDA (perfluortridecansyre), PFBS, PFPeS, PFHxS, PFHpS, PFOS, PFNS, PFDS, PFUnDS, PFDoDS, PFTrDS, PFOSA, 6:2 FTS. PFAS 4 are marked with bold

Beyond meeting regulatory requirements, Krüger is using this pilot project to validate the results from our laboratory research. Our additional objectives include:

- Demonstrating effective treatment of PFAS in soil at optimized temperatures

- Minimizing energy consumption without compromising treatment results

- Advancing waste reduction through enhanced PFAS mineralization

How does the pilot project work? Breaking down the setup

The overall setup for treatment of 36 tons of PFAS-contaminated soil includes:

- A hermetically closed carbon steel heated box equipped with 15 heaters

- The patent-pending DeFluorinator on the outgassing from the heated box

- A scrubber and cooling system to neutralise any acid production

- Storage tanks for condensate (for subsequent treatment at the existing storm/drainage water treatment plant on site)

- Blower to ventilate extracted vapors

- Activated carbon filters for treatment of the outgassing vapors

What are we measuring? Understanding the monitoring program

In order to keep track of treatment effectiveness and system performance, a quite comprehensive monitoring program is incorporated. First of all, numerous thermocouples are installed throughout the soil mass. These sensors provide precise information on temperature distribution, enabling us to track exactly how long different zones of the PFAS-contaminated soil and vapors have been exposed to specific temperatures.

Continuous online monitoring also tracks parameters such as flow rates, pressure conditions, and condensate production. This comprehensive data allows us to document the exact conditions during the field demonstration and provides valuable insights into the treatment performance. These insights can be crucial for design and optimization of future full-scale soil remediation setups.

In order to monitor the outgassing at two critical points — at the heated box outlet and after the DeFlourinator — a High Resolution Mass Spectrometer is coupled to the system. This setup not only provides the real time monitoring of the extracted gasses, but will also reveal if it is possible to operate such a delicate instrument under field conditions.

Furthermore, the following analysis program is performed during the testing.

| Sample location | Parameters |

| Soil (1) | PFAS 22, PFAS 35 TOPA, NTA, TOF, EOF, water soluble F |

| Vapor (1, 2, 6) | OTM 45, OTM 50, NTA of OTM 45 extracts, HRMS real time |

| DeFlourinator catalyst (2) | PFAS 22, EOF, water soluble F |

| Condensate (4) | PFAS 22, PFAS 35 TOPA, NTA, TOF, AOF, F in aqueous solution |

| GAC (6) | PFAS 22 |

TOPA: Total Oxidizable Precursor Assey

NTA: Non Target Analysis

TOF: Total Organic Fluorine

EOF: Extractable Organic Fluorine

OTM: US EPA Other Test Method. OTM 45: semi volatile PFAS, OTM 50: volatile PFAS

F: Fluorine. Water soluble F is inorganic fluorine (fluoride)

From theory to practice: Initial results and observations

The pilot facility was constructed in January 2025, and the heated box was filled with 32 tons of PFAS-contaminated soil. In early February, we started heating the soil to dry it out. To minimize PFAS outgassing and chemical reactions, the drying stage is executed with low input on the heaters.

The graph below shows the 18 temperature monitoring points inside the heated soil volume — approximately 1 sensor per m³ of soil. This comprehensive monitoring allows us to track what temperatures the soil has been exposed to during treatment.

After about 10 days of gentle heating, the entire box reaches boiling temperature. Over a period of 30 days, as the soil dries out, the respective soil temperatures rise above the boiling point of water.

A total of 4,500 l of water has been evaporated from the soil and condensed. All condensate is collected in IBCs (Intermediate Bulk Containers) and is being tested for PFAS compounds as shown in the previous monitoring table. Results are still to come.

During the dry out phase, we observe that the condensate is acidic, with pH levels decreasing from 6 to 5. Interestingly, the water collected after the dry-out phase (mineral bound water and water generated from oxidation of organic material) showed a neutral pH.

Real time monitoring: Can mass spectrometry work in field conditions?

A High Resolution Mass Spectrometer (TOF-MS) has been installed to track and identify PFAS compounds during treatment. The instrument can be equipped with two different ionization reactors — iodine AIM and PTR-O2: — each offering unique sensitivity to different fluorinated compounds.

Mass Spectrometer serves two key purposes:

- To identify which compounds are released and when during the treatment process.

- To evaluate whether mass spectrometry can be used for real-world monitoring or if the instrument is too delicate for these conditions.

While we've experienced some challenges maintaining continuous operation, the instrument is now running successfully. Our team is currently analyzing the substantial amount of data collected so far, which will provide valuable insights into the treatment process.

What's next?

Since the soil is dry and there is no longer any steam drive, the soil heating will continue to the target temperature of 350 °C in the box. At this stage, Eurofins will perform OTM 45, and OTM 50 vapor analysis at three key points:

- on the exhaust from the box

- after the Defluorinator

- at the stack after the granular activated carbon filtration

To supplement the standardized OTM 45 the samples will undergo a non target analysis, too.

After these samples we intend to keep the soil at target temperature for approximately 30 days before cooling and soil sampling (one per ton of treated soil).

Stay tuned for the next blog post, where we hope to reveal results from both the condensate and the vapor analyses.

Be sure that you have subscribed to our newsletter to get project updates and webinar invite.

The information contained herein is based on the Veolia group's understanding and know-how of the scientific, regulatory and technical fields discussed herein as of the time of publication. No contractual undertaking or offer is made on the basis hereof and no representation or warranty is given as to the accuracy, completeness or suitability for the purpose of the relevant information.